Our core focus

An overview of our actions and progress in reducing our carbon footprint.

-

Shift to low-emission fuels

Transitioning to low-emission fuels such as LNG, biomass, and hydrogen.

-

Energy efficiency

Optimising processes and upgrading

technology to enhance energy efficiency. -

Carbon capture and utilisation

Implementing advanced carbon capture

for pharmaceutical-grade bicarbonate. -

Renewable energy

Harnessing solar, wind, and

hybrid renewable energy solutions.

Our commitment to the environment

-

Reduce carbon emission to achieve neutrality by 2045.

-

Become water positive and achieve zero waste to landfill in India by 2030.

-

Double the share of renewable power by 2025.

-

Achieve net-zero impact on biodiversity.

-

Restore coastal and marine ecosystems.

Our key projects under project Aalingana

-

Biomass for a greener tomorrow

Switching to sustainable heating by increasing biomass use to reduce carbon footprint and promote renewable energy alternatives.

-

Powering progress with renewable energy

Enhancing our energy mix with a growing share of renewable power, paving the way for a cleaner, greener future.

-

Efficiency that powers impact

Driving energy efficiencies across all our manufacturing units to lower emissions and maximize resource utilization.

-

Fueling the future with hydrogen

Partnering in offtake agreements for hydrogen and other sustainable fuels to transition towards low-emission energy sources.

-

100% fly ash utilisation

Ensuring zero waste of fly ash through complete consumption in eco-friendly applications, promoting circular economy principles.

-

Recycling over 3 lakh MT solid waste

Turning waste into opportunity by recycling massive quantities of solid waste, supporting a zero-to-landfill approach.

-

Green chemistry in action

Developing sustainable chemistries for fermentation technologies, aligning innovation with environmental stewardship.

-

Meeting EPR goals responsibly

Adhering to Extended Producer Responsibility (EPR) norms to ensure responsible product lifecycle management.

-

Smarter processes, better planet

Leveraging IIoT (Industrial Internet of Things) for enhanced process efficiencies and productivity across operations.

-

10% more renewable power

Achieving a 2,284 GJ increase in renewable energy consumption — a 10% boost in our clean energy efforts.

-

Protecting biodiversity, preserving balance

Working to minimize our ecological footprint and actively reduce our negative impact on biodiversity.

-

Saving sharks, sustaining ecosystems

Conserving marine life by safeguarding over 900 sharks, contributing to the protection of underwater ecosystems.

-

Restoring nature, one coral and tree at a time

Investing in coral reef restoration, mangrove protection, and tree plantations to nurture and revive biodiversity.

Strategic initiatives

- Climate change

- Energy

- Water management

- Waste management

- Raw material consumption

- Air emissions

-

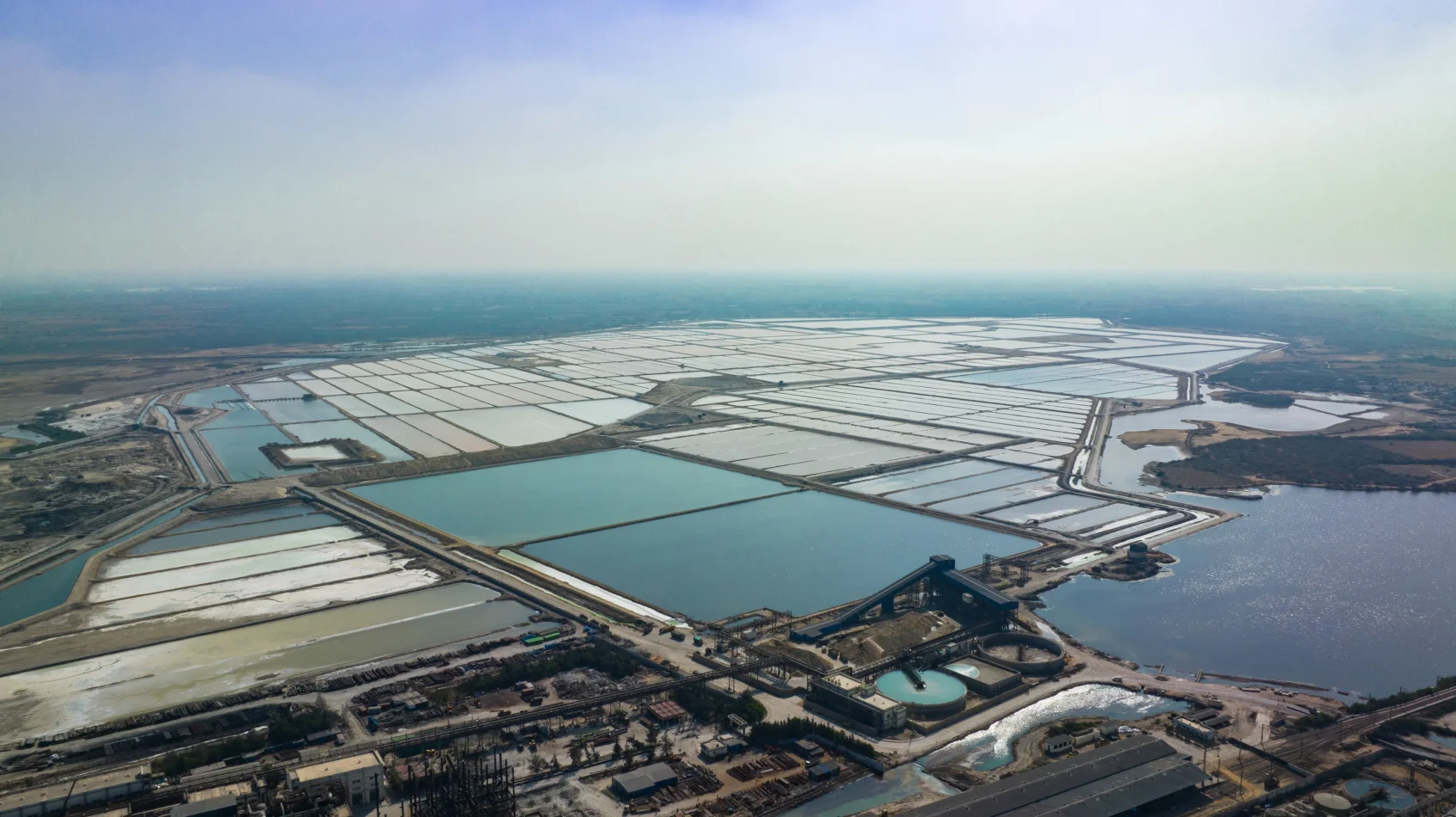

Making process improvements to reduce carbon emissions

Tata Chemicals is boosting sustainability at the Mithapur salt plant by enhancing energy efficiency and cutting carbon emissions. These efforts highlight the company’s commitment to environmental responsibility.

-

Goal

Reduce carbon emissions to achieve neutrality by 2045.

-

Progress

At the Mithapur salt plant, we reduced carbon emissions by about 15MT CO2e annually by improving steam efficiency and fixing leaks in quadruple-effect evaporators. Upgrading a double-effect evaporator to a triple/quadruple effect is projected to cut emissions by an additional 19MT CO2e per year through better energy efficiency.

-

Transitioning to low-emission fuels

Low-emission fuels are critical to the accomplishment of our decarbonisation goals. We have taken several initiatives to steer this transition across our operations.

-

Goal

To scale up biomass procurement in FY 2024-25 to replace ~10% of coal usage.

To establish a dependable supply chain, including energy crop plantation, to ensure consistent access to biomass. -

Progress

Signed an offtake agreement with Vertex Hydrogen, UK, for the supply of over 200 MW of low-carbon hydrogen. In India, we successfully conducted trials for the use of biomass in our current boilers during FY 2023-24.

-

Carbon Capture and Utilisation (CCU)

Tata Chemicals leads efforts to capture carbon emissions and convert them into usable products.

-

Goal

Implement carbon capture across key manufacturing sites.

-

Progress

Successfully implemented Europe’s first CCU plant to capture and convert CO₂ emissions into high-grade products like Sodium Bicarbonate for the pharmaceutical industry.

-

Renewable energy expansion

In Kenya, we are piloting the use of electric calciner technology to reduce the carbon footprint and improve the whiteness index from 87 to 94.

-

Goal

Double the share of renewable power by 2025

-

Progress

- Installed 2.7 MW of solar power across Indian facilities and plans to increase biomass usage in operations.

- In Kenya, we are piloting the use of electric calciner technology to reduce the carbon footprint and improve the whiteness index from 87 to 94.

-

Energy efficiency projects

Tata Chemicals is focused on improving energy efficiency across its manufacturing plants.

-

Goal

Reduce energy consumption intensity by implementing energy-efficient technologies.

-

Progress

Achieved an energy consumption intensity of 8.33 GJ/tonne in FY 2023-24 through optimised energy usage and enhanced operational processes across facilities.

-

Jal dhan project

Focuses on rainwater harvesting and groundwater recharge to ensure long-term water availability.

-

Goal

Replenish freshwater used across operations by 2030.

-

Progress

Harvested 25.5 mcft of water in FY 2023-24 and built 149 small and medium water harvesting structures across operational areas.

-

Zero waste to landfill programme

Aims to divert all waste from landfills by maximising recycling and reuse.

-

Goal

Achieve zero waste to landfill by 2030.

-

Progress

Achieved 100% Fly Ash utilisation and reused over 3 lakh metric tonnes of undersized limestone in FY 2023-24.

-

Circular economy in cement production

Tata Chemicals' cement plant uses waste generated from soda ash production as raw material, reducing waste and supporting circularity.

-

Goal

Maximise the use of waste materials in cement production and promote circular economy principles.

-

Progress

Significant progress in integrating waste into cement manufacturing, reducing dependency on virgin materials.

-

Utilisation of recycled Fly Ash

Fly Ash from operations is fully recycled and used in various applications, such as cement production and land reclamation.

-

Goal

Ensure 100% utilisation of Fly Ash and other recyclable materials.

-

Progress

Achieved 100% Fly Ash utilisation in FY 2023-24, diverting waste from landfills and promoting circular material use.

-

Recycling undersized limestone

Undersized limestone is reused in production, reducing waste and improving resource efficiency.

-

Goal

Maximise the use of recycled materials in production.

-

Progress

Recycled over 3 lakh metric tonnes of undersized limestone in FY 2023-24, contributing to resource conservation and waste reduction.

-

Clean air initiative

Tata Chemicals is implementing air quality management systems to reduce NOx, SOx, and particulate matter emissions.

-

Goal

Ensure air emissions are kept well below regulatory limits.

-

Progress

The company maintained emissions of NOx, SOx, and SPM below permissible limits through continuous monitoring and the adoption of cleaner technologies.

Get in touch

Have any questions? Our team is ready to assist you.